Vikhroli, Mumbai, Maharashtra

- GST NO. : 27ADGPC6511R1ZA

Oil Expellers

Leading Manufacturers, Exporters and Wholesaler of Baby Oil Expeller, Super Oil Expeller, Heavy Duty Oil Expeller, Super 20 Oil Expeller, Mark 20 Oil Expeller and Mark 30 Oil Expeller from Mumbai.

| Business Type | Manufacturer, Exporter, Supplier |

| Specialities | Easy To Operate |

| Bearing | Ball Bearings are Fitted to this Machine in Order to Consume Less Horsepower |

| Thrust Frame | The Thrust Frame is Fitted with a Simple and Rigid Arrangement to Withstand the Back Pressure of The |

| Side Belt Drive | The Expeller is Fitted with Loose and Fast Pulleys. |

| Horse Power | 7 to 8 B.H.P |

| Weight | Approx 2 Tons |

Preferred Buyer From

| Location | Worldwide |

Trimurti Baby Oil Expellers are economical as compared with rotary Ghani as the capacity Is about 5-6 times that of a power-driven Ghani. The oil left in the cake when crushed by TRIMURTI BABY OIL EXPELLERis about 7-8% whereas Ghani cake seldom contains less than 13% depreciation value of TRIMURTI BABY OIL EXPELLER is very low as compared to Ghani, where the pestle and mortal require frequent replacements

OUTSTANDING FEATURES OF THE TRIMURTI BABY OIL EXPELLER ARE :

GEARS :

All the gears are made of high-grade material and milling cut teeth.

BEARING :

Ball bearings are fitted to this machine in order to consume less horsepower.

MAIN WORM SHAFT SNARES :

The wear and tear parts are made out of case hardening steel to ensure carefree and long service. All these parts are case hardened in an up to date electric case hardening furnace.

THRUST FRAME :

The thrust frame is fitted with a simple and rigid arrangement to withstand the backpressure of the main worm shaft.

CONE POINT :

The size of the cake to be discharged is regulated by a simple gear arrangement that moves the cone in and out.

SIDE BELT DRIVE :

The expeller is fitted with loose and fast pulleys.

HORSEPOWER :

The TRIMURTI BABY OIL EXPELLER requires 7 to 8 B.H.P.

CRUSHING CAPACITY :

The TRIMURTI BABY OIL EXPELLER can crush over 4 tons of seed in 24 working hours under normal conditions. Depending upon the nature, kind, and quality of the seeds. If it is to extract oil from oil cake, the capacity to crush oil cakes is 3 Tons.

WEIGHT :

Approx 2 tons

SPACE :

The space required for the erection is 8′ x 4′

Note: We reserve the right to make alterations to the machine from time to time as required.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Shape | Rectangular |

| Specialities | Easy To Operate |

| Packaging Type | Wooden Box |

Preferred Buyer From

| Location | Worldwide |

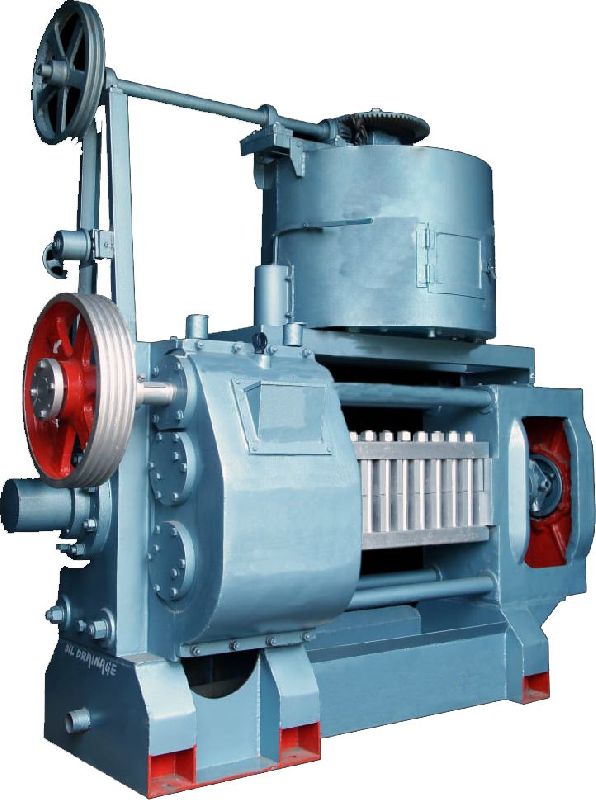

TRIMURTI EXPELLERS are the result of many years of experience in the manufacturing of Oil Expellers. The expellers can be used in crushing Cashew Nut Shell, Copra, Cotton Seed, Ground Nut, Sun Flower, Soya Bean, and Palm-Kernels.

GEARBOX

All gears are made out of steel, are hardened, and are enclosed in an oil bath to prevent wear & tear. Gears are mounted on ball bearings. Hence ensuring smooth functioning.

HEATING KETTLE

Expellers can be provided with single, double, or three-stage heating kettles. The kettle jackets are made out of 12 mm (½”) thick plate and the outer shell is out of 6 mm. (¼”) thick plate. The kettle has four bearings.

CHAMBER

Made of M.S. Plates of 32 mm (1 ¼”) and 25″ mm (1″) plates to ensure better fitting of the cage bar, hence better crushing and a maximum output of oil. The chamber is hinged in the machine in such a manner that it opens like a book and worms and other spares can be inspected and changed without removing the chamber on the ground thus saving lots of time in the opening and restarting of the expellers.

The expeller body is very sturdy, fitted with heavy-duty bearings which help in the smooth running of the machine. There are nine bearings in the expeller and four in the kettle. Total 13 bearing base of the explorer is fabricated out of channels, plates and flats give stability and sturdiness to the expeller. We can provide the independent self-drive for the kettle, both independent gearbox and motor at an extra cost.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Metal |

| Warranty | 1 Year |

| Specialities | Easy To Operate |

| Usage | Peanut Oil |

Preferred Buyer From

| Location | Worldwide |

TRIMURTI EXPELLERS are the result of many years of experience in manu acturing of oil Expellers. The expellers can be used in crushing Cashew Nut Shell, Copra, Cotton Seed, Ground Nut, Sun Flower, Soya Bean and Palm-Kernels.

GEAR BOX

All gears are made out of steel, are hardened and are enclosed in an oil bath to prevent wear & tear. Gears are mounted on ball bearings. Hence ensuring smooth functioning.

HEATING KETTLE

Expellers can be provided with single, double or three stage heating kettles. The kettle jackets are made o of 12 mm (1/2") thick plate and outer shell is out of 6 mm. (1/4") thick plate. Kettle has four bearings.

CHAMBER

Made of M.S. Plates of 32 mm (1 1/4") and 25" mm (1") plates to ensure better fitting of the cage bar, hence better crushing and maximum output of oil. The chamber is hinged in the machine in such a manner that it opens like a book and worms and other spares can be inspected and changed without removing the chamber on the ground thus saving lots of time in the opening and restarting of the expellers.

Expeller body is very sturdy, fitted with heavy duty bearings which help in the smooth running of the machine. There are nine bearings in the expeller and four in the kettle. Total 13 bearing base of the explorer is fabricated out of channels, plates and flats give stability and sturdiness to the expeller. We can provide independent self drive for the kettle, both independent gear box and motor at an extra cost.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Operating Type | Manual |

| Specialities | Easy To Operate |

| Packaging Type | Wooden Box |

| Usage | Soybean Oil, Peanut Oil, Sunflower Oil |

Preferred Buyer From

| Location | Worldwide |

Trimurti oil machinery is being used in oil mills in India and may overseas countries for over 37 years. We have always offered expellers with latest features of efficient working and labor-saving devices. The latest demand of high capacity, high yield, and sturdy expellers being met with our offer of TRIMURTI SUPER 20 AUTOMATIC EXPELLER. SUPER 20 expeller is in a class by itself with its unique feature. Our experienced personnel in manufacturing and sales divisions have spared no effort to design this expeller to possess study built, easy installation, operation, smooth working and also satisfying the specific requirements of oil millers.

SUPER 20 possesses the following features.

CONSTRUCTION:

The sturdy close grain first grade cast iron frame is fitted on one piece fabricated oil tray. The frame is machined throughout in one selting to give perfect alignment of bearings, shafts and other parts. This reduces Static and Dynamic friction and saves greatly on power consumption

CHAMBER BOX:

it is vertically hinged and opens like a book and spares the trouble of removing it from expeller during a change of cage bars and worms. This is a great time and labor-saving improvement.

SUPER 20 Expeller is offered in two models :

SINGLE PRESS DOUBLE CHAMBER EXPELLER:

This model has two independent chamber 1st chamber length 22” X9” diameter and 2nd chamber is having a length of 27″X7″ diameter with a center body ring of 3″ width. This is a very high-pressure machine and leaves 6% to 7% oil in a cake in a single pressing

FIRST PRESSING SINGLE CHAMBER EXPELLER:

Having a length 52″X9″ diameter. This is used as a 1st pressing machine to feed other Expeller for 2nd pressing.

COOKING KETTLE:

The Expeller is fitted with a THREE STAGE cooking kettle. It is compact in design and is fitted with a self-controlled meal inlet to prevent overflowing. It is also fitted with a safety valve, pressure, gauge, steam traps, steam valve, and steam damping apparatus. The steam is welded and riveted and listed jackets to 100lbs. Pressure per square inch. The kettle requires 100-120 lbs. of process steam per hour at a pressure of 60 lbs. per square inch to be supplied from a separate boiler.

POWER:

The power required depends upon the material being crushed and how well it has been cooked. The normal requirement for usual seeds is 70-75 BHP

LUBRICATION:

The expeller is fitted with a self-lubricating reduction Gear Box. Main gears are steel fabricated and tempered, they also run in their own oil bath thus ensuring long life to all these gears. Stuffer lubricators are fitted on other bearings as standard fittings. High-pressure grease gun lubrication can be fitted if desired at an extra cost.

CAPACITY:

It varies from seed and also whether the expeller is being used for first or second crushing. The efficient cooking, preliminary crushing, and large capacity chamber box in thus expeller give the following crushing capacity of 24 hour working.

- Copra first crushing : 25 – 30 tons

- Copra second crushing : 20 – 22 tons

- Ground nut : 18 – 20 tons

- Cottonseed: 18 – 20 tons

- The oil left in the final cake is about 6-7%

MOTOR DRIVE ARRANGEMENT :

This expeller is usually supplied with a belt drive arrangement. If the motorized unit is desired, the same can be supplied at an extra cost.

DURABILITY :

All parts subject to heavy wear and tear such as worms cage bars cone points are made from case hardening steel (special alloy steel) and properly heat treated to give long life, high capacity, and low maintenance cost. Standard Equipment includes spanners, pressure gauges, steam traps, etc., etc. We reserve the right to alter the design and dimension without any prior notice at any time if the necessity arises.

Note: We reserve the right to make alterations to the machine from time to time as required.

| Business Type | Manufacturer, Exporter, Supplier |

| Specialities | Easy To Operate |

| Finishing | Polished |

| No. of Chamber | 2 |

| Chamber Length | 22 and 33 Inch |

| Worm Diameter | 9 & 8 Inch |

Preferred Buyer From

| Location | Worldwide |

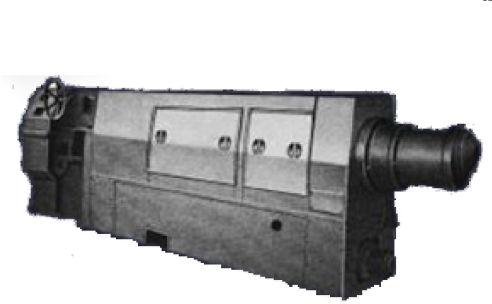

TRIMURTI OIL MACHINERY is being used satisfactorily in India and many overseas countries for over 40 years. Our models incorporate the latest international design specifications and technological developments. The enhanced efficiency thus obtained gives you savings in terms of time, money, and labor. TRIMURTIMARK 20 OIL EXPELLER and TRIMURTIMARK 30 OIL EXPELLER, our 2 recent models, meet the demand of high capacity high yield expellers. Our designers have spared no effort to make these models strong and sturdy. TRIMURTIOIL MACHINERY is easy to install and gives you long trouble-free service. 20, MARK 30 OIL EXPELLERS Crushes in a single pressing operation approximately 20 tons to 30 tons oil seeds in 24 hours and leaves behind 5% to 6% oil in the cake.

CHAMBER BOX

Being vertically hinged it opens like a book and saves the trouble of removing it from expeller during a change of worms. This is a great time and labor-saving improvement.

COOLING OF CHAMBER

Oil from the oil settling tank is pumped and sprayed by a special motorized pump which is part of the standard equipment. Oil thus flushed on the chamber removes the feet and also cools the chambers. As a consequence, the life of the spare parts is enhanced.

GEARBOX

The gearbox is robust and of close-grained C.I. Casting fitted with heavy bearings and tempered helical steel gears that run in an oil bath. These hobbing cut teeth gears run silently and have a long life.

BODY AND CENTER BODIES

These are fabricated from tested steel plates.

PRELIMINARY COMPRESSION

The cooked meal from the kettle is compressed and consolidated by a packing worm before entering the chamber box, where oil extraction starts immediately. The packing worm is driven by an automatic tension belt which stops whenever the feed is excessive and starts again as the accumulated material has been taken over the feed worm.

MAIN WORM SHAFT WITH WATER COOLING ARRANGEMENT

The worm shaft is of special alloy steel of high tensile strength to withstanding shock and strain. It is stepped in design to assist the easy withdrawal of worms and collars. The shaft can be removed without disturbing the main thrust bearing and main gears. It is equipped with the necessary motorized pump for water cooling arrangement.

COOKING KETTLE

MARK – 20

The expeller is fitted with a FOUR stage cooking kettle. it is compact in design and is fitted with a self-controlled meal inlet to prevent overfeeding. It also fitted with a safety valve, a pressure gauge, steam traps, a steam valve, and a steam damping apparatus. It is independently driven by a 20 HP motor through a reduction gearbox.

FLOW OF OIL AND FOOTS FROM EXPELLER

A conveyor is provided in the oil tray of the expeller which conveys oil and feet to oil storage tanks.

POWER

The power required depends upon the material being crushed and how well it has been cooked. The normal requirement for usual seeds is

- MARK – 20 75HP 1000 RPM

- MARK – 30 125HP 1000 RPM

CAKE

The thickness of the cake at the discharge is controlled by an automatic mechanism that can be operated to increase or decrease the cake thickness even while the expeller is in motion.

DURABILITY

All those parts of which are subject to heavy wear and tear such as worms, cage bars, cone points, etc. made from special alloy steel, are properly hardened and tempered (heat-treated) to give them a long life and a low maintenance cost.

Note: We reserve the right to make alterations to the machine from time to time as required.

| Business Type | Manufacturer, Exporter, Supplier |

| Specialities | Easy To Operate |

| Power | 125 HP 1000 RPM |

| Model | MARK – 30 |

| No. of Chamber | 3 Chamber |

| Chamber Length | 36, 33 and 24 Inch length |

| Worm Diameter | 12, 10 and 9 Inch |

Preferred Buyer From

| Location | Worldwide |

TRIMURTI OIL MACHINERY is being used satisfactorily in India and many overseas countries for over 40 years. Our models incorporate the latest international design specifications and technological developments. The enhanced efficiency thus obtained gives you savings in terms of time, money, and labor. TRIMURTIMARK 20 OIL EXPELLER and TRIMURTIMARK 30 OIL EXPELLER, our 2 recent models, meet the demand of high capacity high yield expellers. Our designers have spared no effort to make these models strong and sturdy. TRIMURTIOIL MACHINERY is easy to install and gives you long trouble-free service. 20, MARK 30 OIL EXPELLERS Crushes in a single pressing operation approximately 20 tons to 30 tons oil seeds in 24 hours and leaves behind 5% to 6% oil in the cake.

CHAMBER BOX

Being vertically hinged it opens like a book and saves the trouble of removing it from expeller during a change of worms. This is a great time and labor-saving improvement.

COOLING OF CHAMBER

Oil from the oil settling tank is pumped and sprayed by a special motorized pump which is part of the standard equipment. Oil thus flushed on the chamber removes the feet and also cools the chambers. As a consequence, the life of the spare parts is enhanced.

GEARBOX

The gearbox is robust and of close-grained C.I. Casting fitted with heavy bearings and tempered helical steel gears that run in an oil bath. These hobbing cut teeth gears run silently and have a long life.

BODY AND CENTER BODIES

These are fabricated from tested steel plates.

PRELIMINARY COMPRESSION

The cooked meal from the kettle is compressed and consolidated by a packing worm before entering the chamber box, where oil extraction starts immediately. The packing worm is driven by an automatic tension belt which stops whenever the feed is excessive and starts again as the accumulated material has been taken over the feed worm.

MAIN WORM SHAFT WITH WATER COOLING ARRANGEMENT

The worm shaft is of special alloy steel of high tensile strength to withstanding shock and strain. It is stepped in design to assist the easy withdrawal of worms and collars. The shaft can be removed without disturbing the main thrust bearing and main gears. It is equipped with the necessary motorized pump for water cooling arrangement.

COOKING KETTLE

MARK – 30

The expeller is fitted with a FIVE stage cooking kettle. It is compact in design and is fitted with a self-controlled meal inlet to prevent overfeeding. It also fitted with a safety valve, a pressure gauge, steam traps, a steam valve, and a steam damping apparatus. It is independently driven by a 20 HP motor through a reduction gearbox.

FLOW OF OIL AND FOOTS FROM EXPELLER

A conveyor is provided in the oil tray of the expeller which conveys oil and feet to oil storage tanks.

POWER

The power required depends upon the material being crushed and how well it has been cooked. The normal requirement for usual seeds is

- MARK – 20 75HP 1000 RPM

- MARK – 30 125HP 1000 RPM

CAKE

The thickness of the cake at the discharge is controlled by an automatic mechanism that can be operated to increase or decrease the cake thickness even while the expeller is in motion.

DURABILITY

All those parts of which are subject to heavy wear and tear such as worms, cage bars, cone points, etc. made from special alloy steel, are properly hardened and tempered (heat-treated) to give them a long life and a low maintenance cost.

Note: We reserve the right to make alterations to the machine from time to time as required.